Designing Electronics Hardware Packaging for Heat, EMI, and Scale

Curious about the types of designs enabled by controlled, low shear polymer processing? If warp, heat, or fragile electronics define your design envelope, this workshop examines a new molding process built specifically for those constraints.

The session focuses on three things: limitations of traditional injection molding, what changes under a low-pressure, low-shear regime, and how those changes open new design space for modern hardware.

Topics include:

Rapid production tooling and broader materials access

Using thermal performance as a design lever

Stress-free molding for complex geometries

In-situ compounding for high-performance materials

How to blend fibers, fillers, or powders at the machine to reach mechanical properties beyond standard pre-compounded resins.

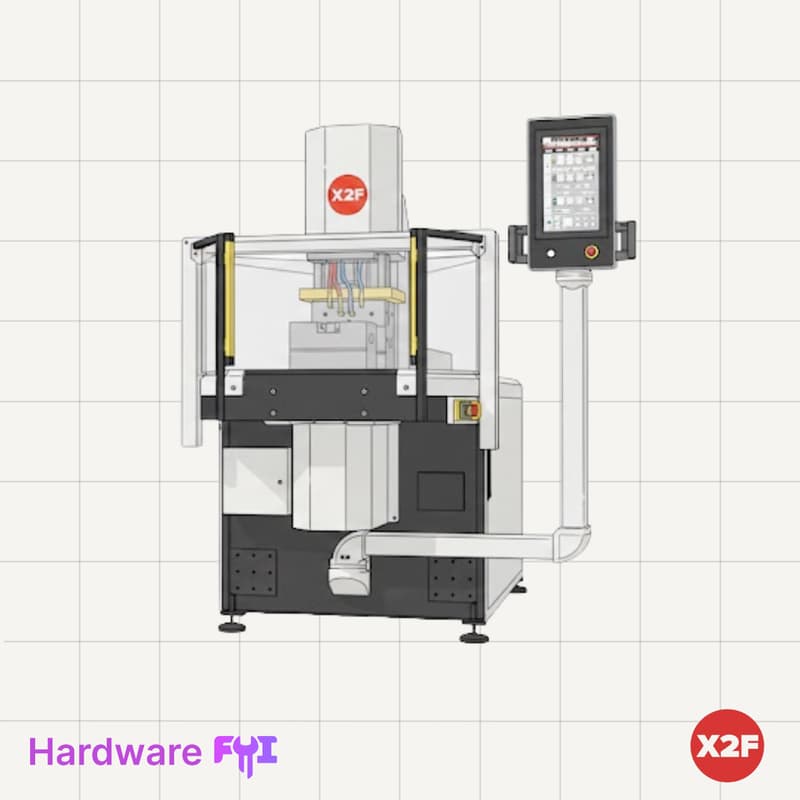

About X2F Manufacturing

X2F is a next-generation molding and material-processing platform for advanced manufacturing. Our technology uses controlled, low-pressure material flow to mold high-viscosity, thermally conductive, and fiber-filled polymers that conventional injection molding can’t process.

About Hardware FYI

Hardware FYI is a weekly newsletter for engineers, founders, and operators building at the intersection of hardware and manufacturing. We cover the latest in engineering and startup funding, with technical insights trusted by 17,500+ subscribers.